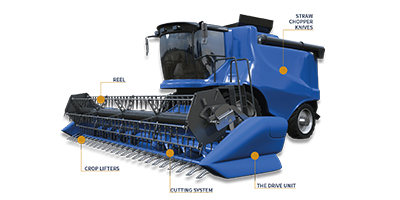

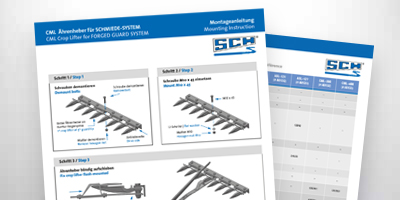

Retrofitting EasyCut

Rob Ewoldt: ‘When someone tells you about a ‘day and night difference’

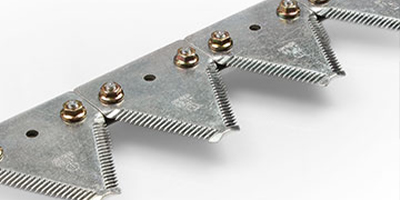

Robert Ewoldt is a corn and soybean farmer in Iowa. He also is Director of the Iowa Soybean Association since 2015, and he had his ears wide open when friends told him about the performance of the Schumacher System. The talks about a ‘day and night difference’ in durability of the cutterbar and the smoother running of the system made him decide to also retrofit the 30 foot flex header of his John Deere 9760 STS combine. We were able to watch the retrofitting and to talk to Rob Ewoldt on his farm.

Robert (Rob) Ewoldt, his wife and their ten and eight year old boys live on the Rafter E. Ranch LLC in Davenport, Iowa. Born in 1973, Rob had thought about becoming a teacher and hence went to a college to get his professional career started. Somewhat disillusioned after two years and following intensive advice from friends who were teachers at that time, Rob changed his mind and started a fresh attempt in agriculture. “To be honest, I have not been one of the busiest guys at college. I spent quite some time working on a farm nearby, and those folks taught me much of what I knew when I started my own farming business”, he recalls.

Rob Ewoldt of Rafter Ranch, Davenport

Rob Ewoldt of Rafter Ranch, Davenport