Pro-Drive

planetary knife drives

Intelligent power transmission

Pro-Drive –

high power

planetary drives

Transmitting power without losses

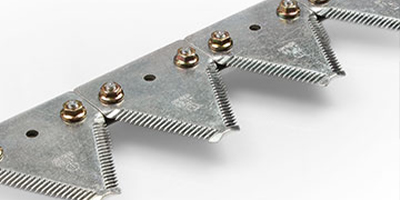

Pro-Drive planetary drives generate an absolutely linear stroke length. Force progression and knife movement are just as linear. The torque available is converted into a linear stroke of the knife without almost any losses. This is the key for maintaining the efficiency of the cutting system especially in difficult harvest conditions.

The Schumacher range of drives offers the perfect solution for every cutting system.

Pro-Drive benefits

Great combine productivity

High cutting frequency

Optimized drivelines

Maximum reliability

Low maintenance

The optimum solution for every cutting system

Pro-Drive

planetary drives

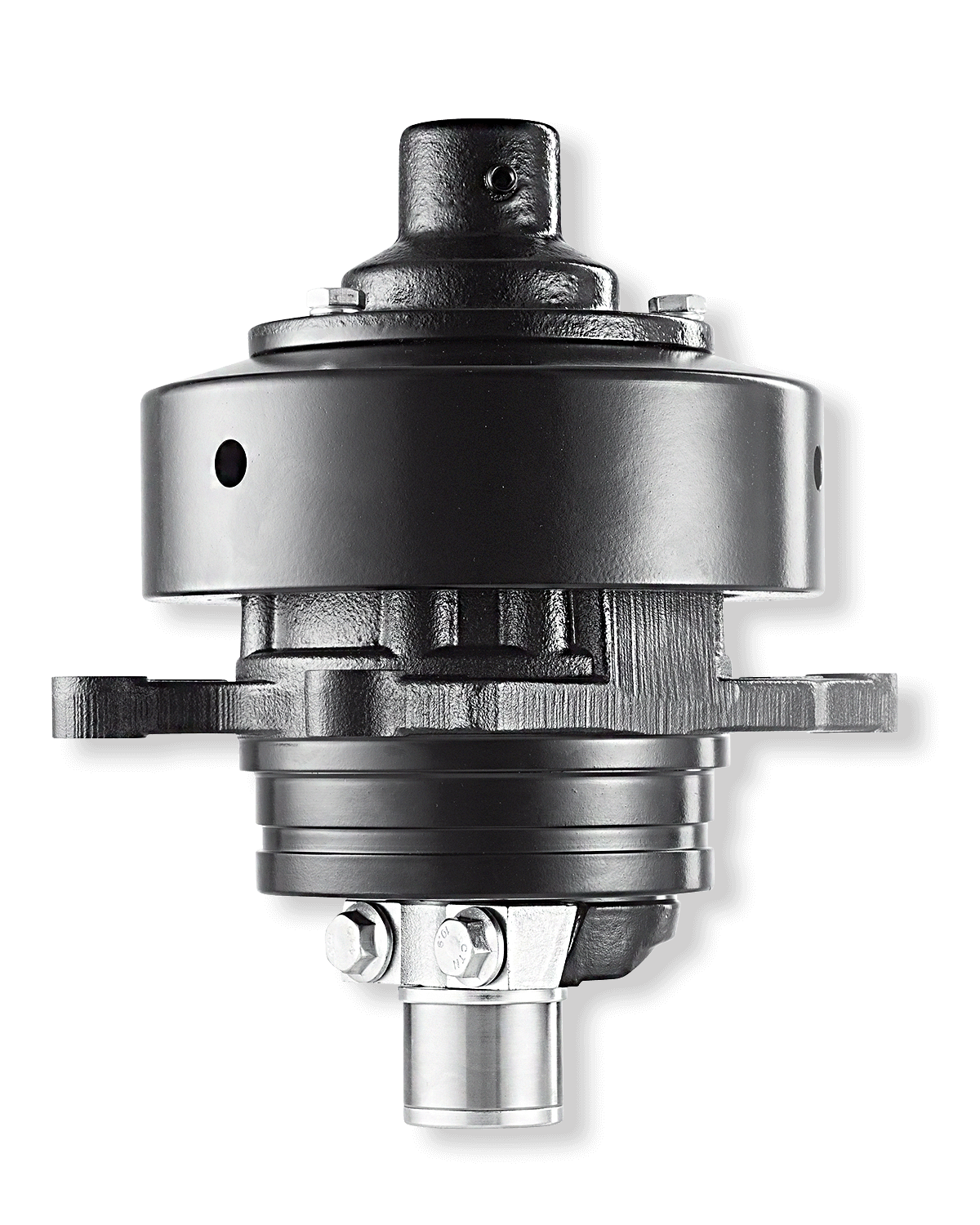

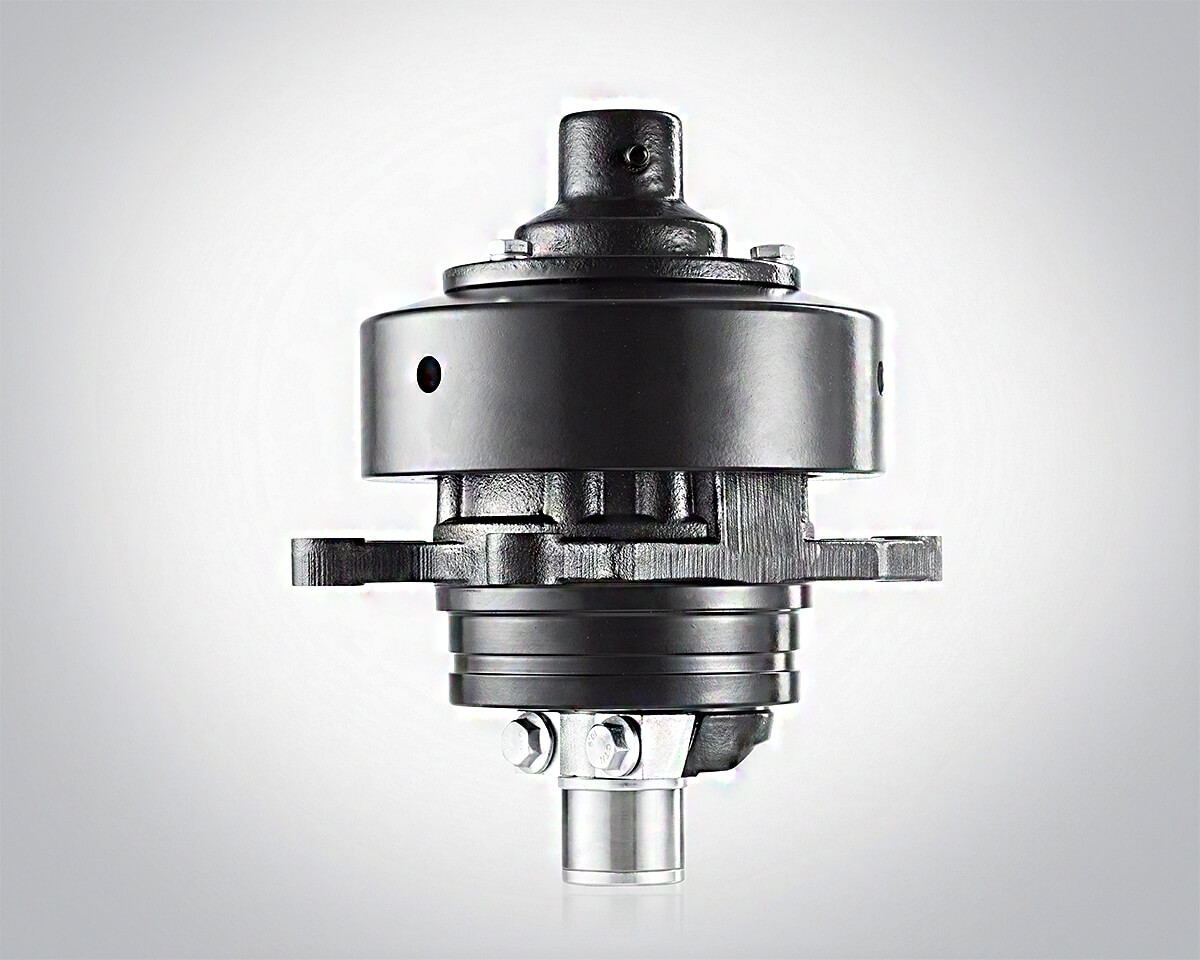

The Pro-Drive Modular series

Made to meet the highest standards, Pro-Drive is the gearbox that powers super wide headers, both rigid and flexible. It is available in two versions that transmit the power either vertically or horizontally into the knife.

Maximum constant power transmission: 10.8 kW

Maximum constant torque transmission: 109 Nm

Maximum rotor speed: 810 rpm

The Pro-Drive Economy series

These drives are made for applications that require less power such as combining canola or sun flower. The power is transmitted vertically or horizontally.

Maximum constant power transmission: 3 KW

Maximum constant torque transmission: 49 Nm

Maximum rotor speed: 600 rpm

Sensor technology for knife drives

The use of sensors on a knife drive allows us to implement a technology that collects data on the cutting system and evaluates these for the purpose of optimizing the throughput. The technology instantly detects any variations in the crop stand for adapting the current forward speed and maintaining a consistent flow of material into the machine. It also detects damage from impacting an obstacle.

The benefits

For optimum forward speeds

Consistent crop flows

Optimum productivity

Reduced operator stress

Solutions for your harvest needs

The Pro-Drive Modular series

For hydro motor powered knives

Pro-Drive 85MH (AS)

This knife drive connects to a hydraulic system. Adapters are available in various sizes to connect to the hydro motor’s output shaft. This drive is typically used on headers with variable tables or variable speed cutter bars.

For cardan shaft powered drives

Pro-Drive 85MH (AS)

This flange-mounted drive was developed for headers and machines that have a cardan shaft to drive the cutter bar. The unit is also available with a regular 1 3/8 inch, six-spline pto shaft as an option. This drive is the unit of choice for headers with variable tables.

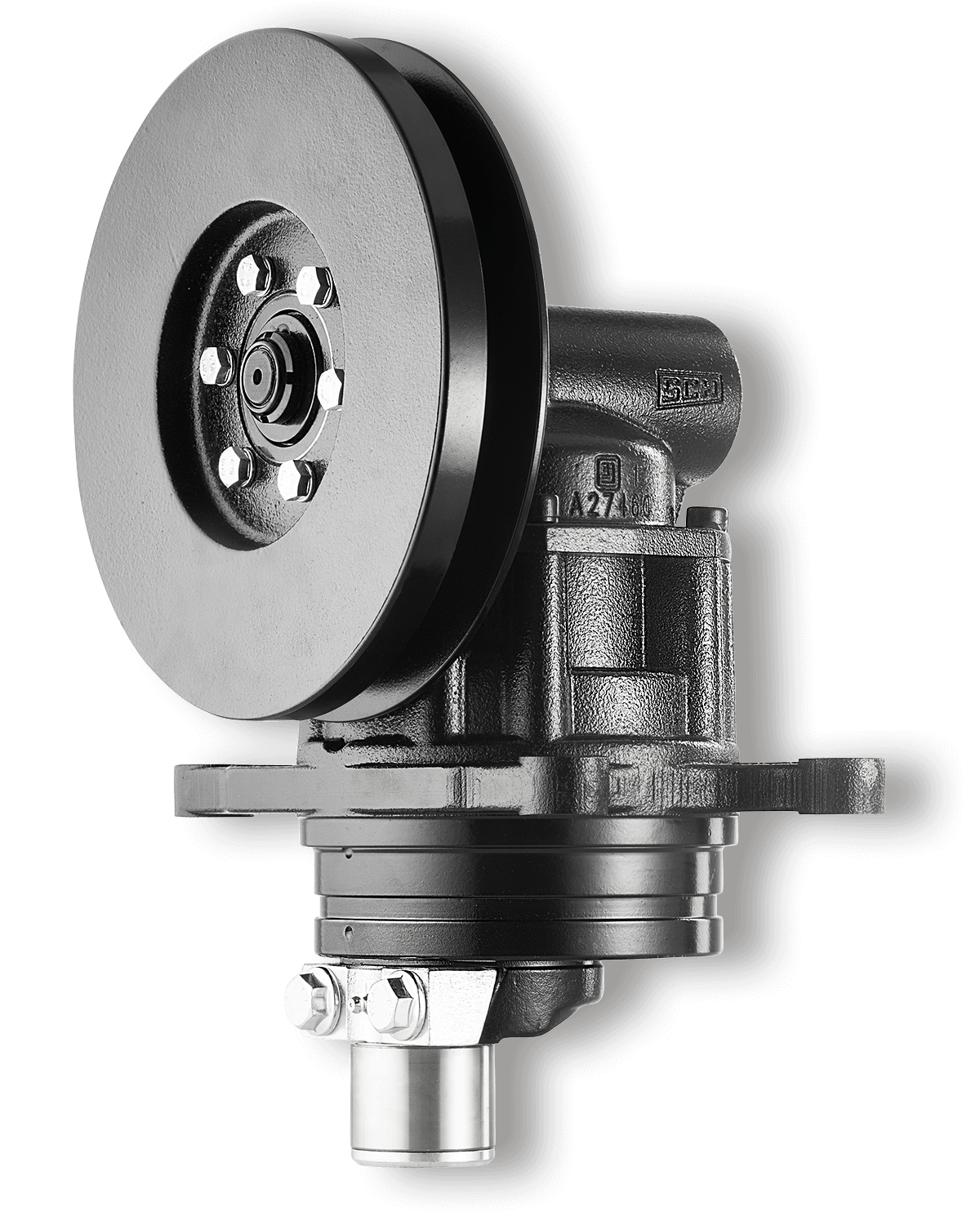

For belt driven knives

Pro-Drive 85MH (RS)

This drive transmits the power to the cutting system via a horizontal pulley. The working diameter of the pulley is customized ex factory. Typically used on standard headers.

For belt driven knives

Pro-Drive 85MV (RS)

This drive transmits the power to the cutting system via a vertical pulley which eliminates a change in direction of the power flow. Multiple variants available ex factory. This versatile drive that is used in a variety of header types.

Pro-Drive Economy series

For belt driven knives

Pro-Drive 80EH (RS)

This compact and light-weight drive unit has a horizontal pulley for direct power transmission to the cutting system. It is particularly suitable for small-width canola and sunflower headers.

For belt driven knives

Pro-Drive 80EV (RS)

This compact and light-weight drive unit has a vertical pulley and an integral angular gearbox which eliminates a change in direction of the power flow. Multiple variants available ex factory.

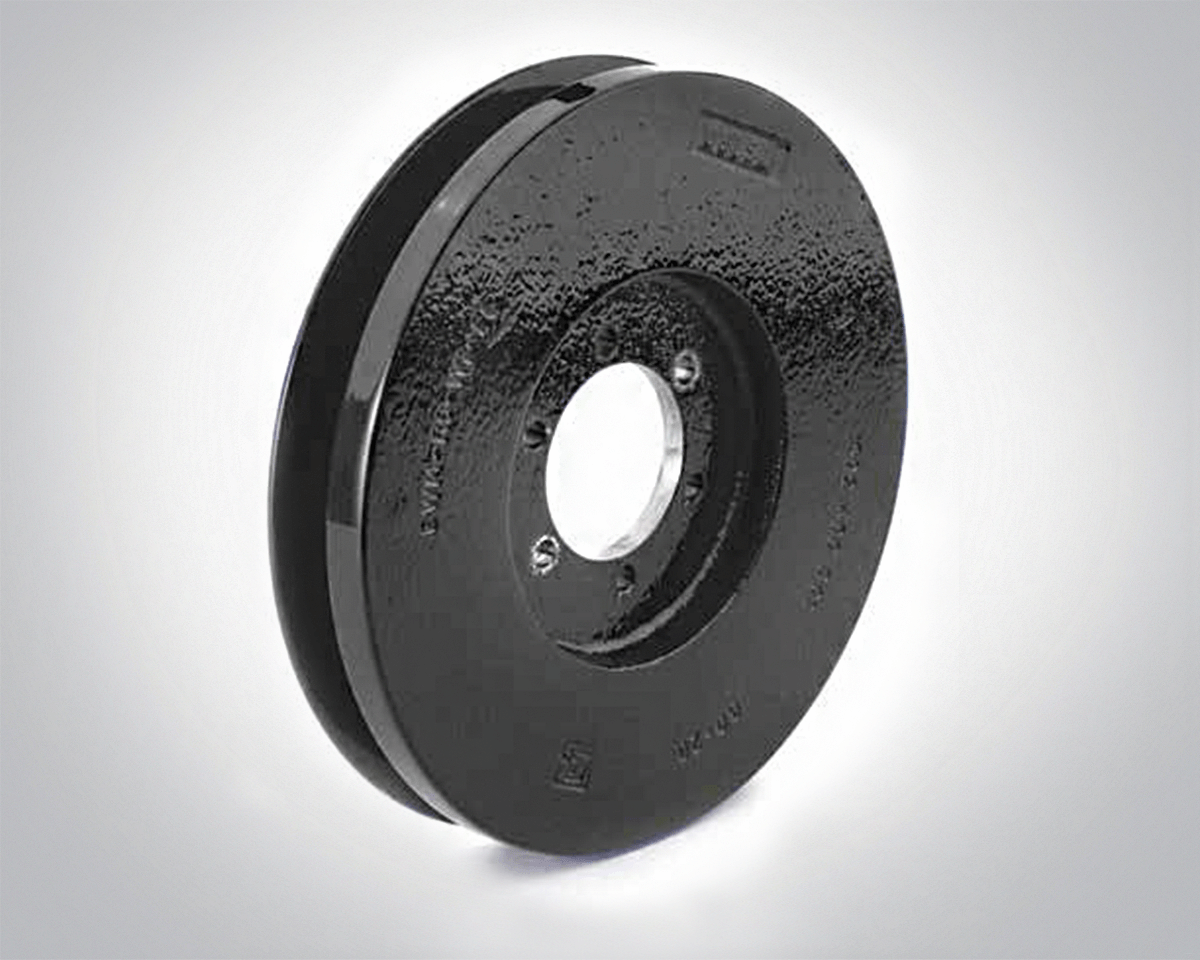

Standard pulleys

Standard pulleys

A large range of pulleys is available in different sizes (7-9 inch diameters) and specifications for the Pro-Drive 85MV (RS) and Pro-Drive 80EV (RS) knife drives. All pulleys have the SPC profile (DIN 7753) as standard. Further pulleys for belt pairs and poly belts are available on request.