Powerful and efficient

Baling

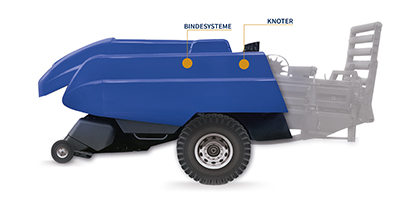

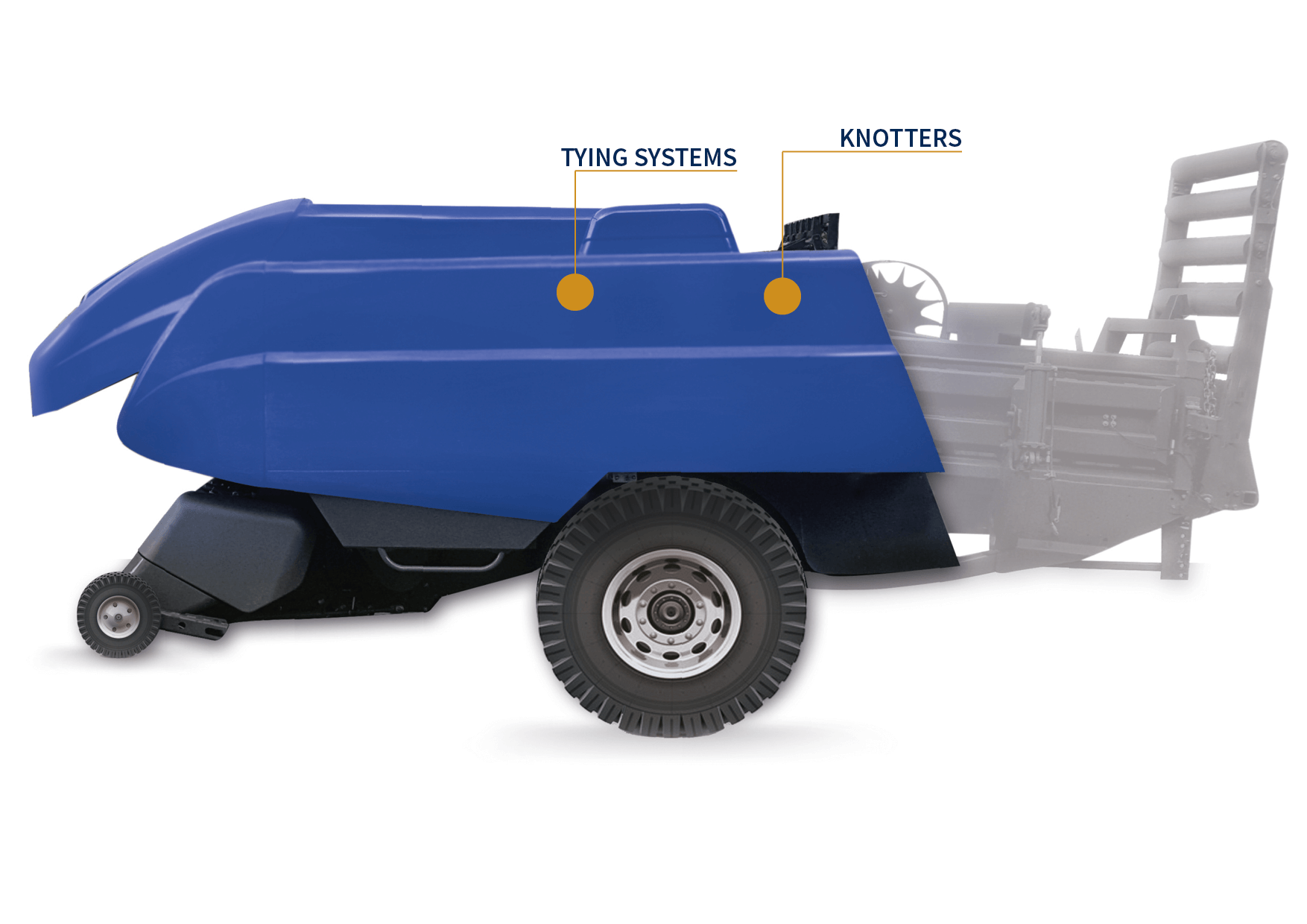

Tying systems

rasspe® tying systems for stationary balers

> Learn more …

Knotters

Single knotters or double knotters – the right technology for each type of baler

> Learn more …

We speak many languages

The technology for knotting and tying

The system specialist

The processes of knotting and tying have a major impact on the overall performance and efficiency of a square baler. We offer technical solutions for different harvesting conditions worldwide. Our single and double knotters ensure tying systems operate reliably and effectively.

For David and Goliath

The best knotter

for each baler

The type of baler is important

Knotters are specified to the type and size of the baler. There are knotters for small balers and big balers. These baler types have different knotter compartments and produce various bale densities and annual outputs.

THINGS TO KNOW

How knotters work

STRING, LOOP AND HYBRID KNOTS

There are two ways of defining a knotter:

By the type of knot it produces or by the tying system.

There are three types of knots – string knots, loop knots and hybrid knots.

Loop knots

Cormick system

The tail is formed into a loop

The knot is made without straining the rope

Maximum utilization of twine strength

String knots

Deering system

The tail end is pulled through the knot

The twine strength is not fully utilized

Hybrid knots

Deering system

One tail end is formed to a loop

One tail end is pulled through the knot

No tail is cut off (Active Tailless Single Knotter technology)

One knot or two knots

The difference between the two tying systems lies in the number of knots produced.

Double knots have enormous advantages for high-density square balers.

Single knotter

Each knotter handles one twine

Each twine is tied into one knot

The tail is pinched by the retainer while the bale is being built in the chamber

Double knotter

Each knotter ties one twine which is split into an upper and lower thread

Each twine is tied into two knots

The twines are not under tension as the bale is being formed in the chamber

Knotter program

LOOP KNOTSCormick system |

STRING KNOTSDeering system |

HYBRID KNOTSDeering system |

|

Single knotter |

RS 8000 |

RS 6002, RS 6003RS 6004, RS 6006RS 6101 |

RS 6003, RS 6101 |

Double knotter |

RS 9000 |

RS 1450, RS 6131RS 8800 |

Baling

Knotter technology

Single knotters

Single knotters are typically used on balers with 2 or 3 knotters. HDC (High Duty Combination) variants are found on square balers where 4 to 6 knotters are arranged on each drive shaft.

For small and big balers

For hay, straw and silage bales

For high-density bales

Available with retrofit auto lubricator

Double knotters

Double knotters for high-density balers and high-duty knotter systems have up to 8 knotter modules on each drive shaft.

For big balers

For hay, straw and silage bales

For highest-density bales

HDC double knotter

Double loop knotter

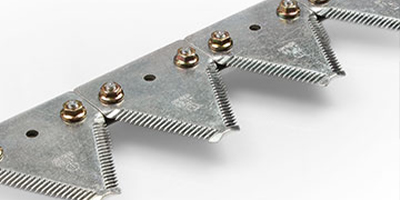

Knotter parts

Made in line with the highest quality standards, these knotter parts are refined to the highest levels of precision and maximum reliability.